AIET |

Consult

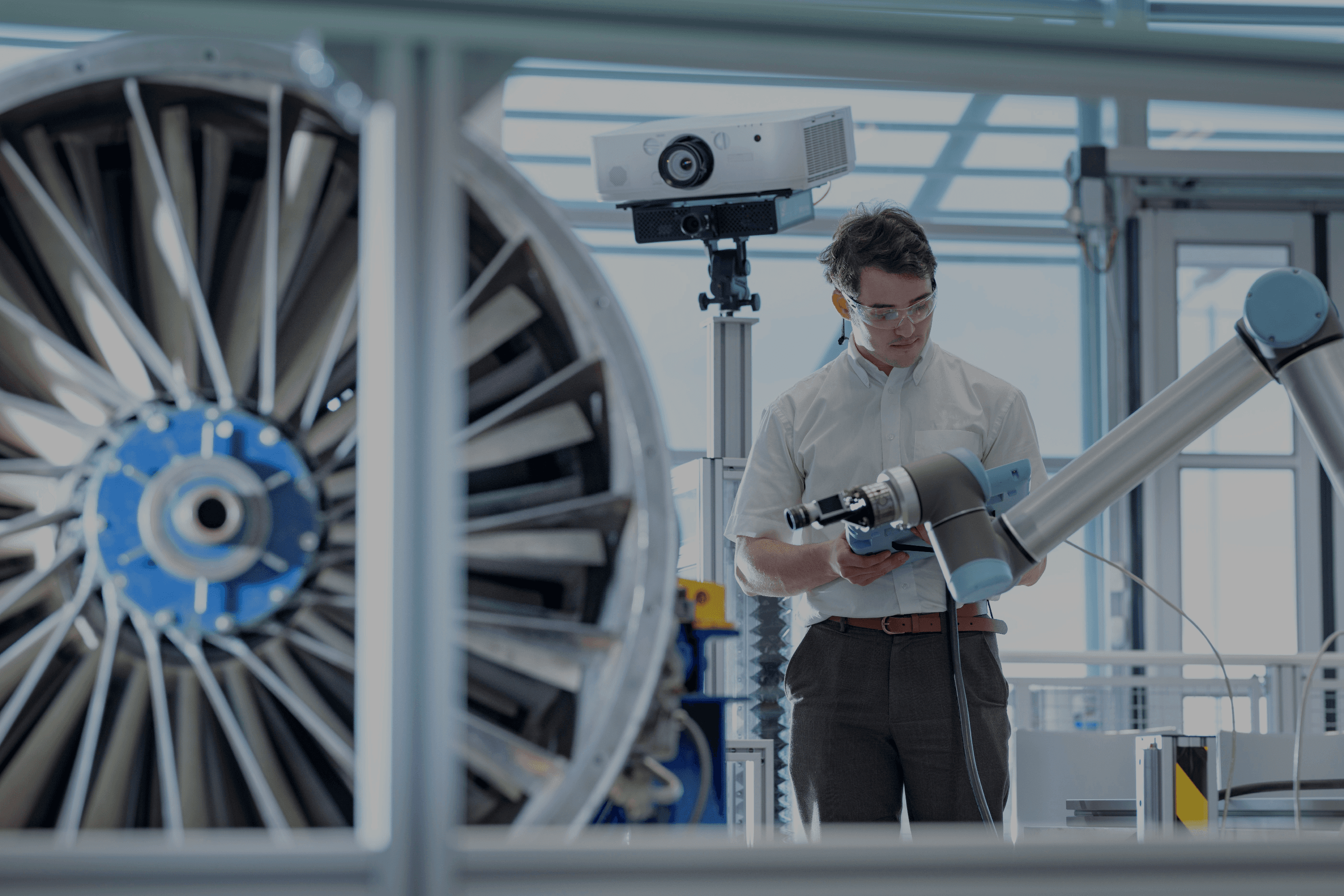

Advanced Manufacturing Consultancy for Smart, Regulated Industry

Independent technical advisory across machine vision, automation, robotics, and digital quality — helping UAE manufacturers reduce scrap, improve throughput, and prove compliance.

End-to-End Consultancy for Smart, Regulated Manufacturing

End-to-End Consultancy for Smart, Regulated Manufacturing

We support manufacturers at every stage of the automation lifecycle — defining requirements, specifying systems, managing risk, and ensuring solutions perform safely, reliably, and in conformance with standards.

Consultancy & Feasibility

Early-stage assessments, process reviews, sample evaluation, and ROI analysis — establishing whether automation is viable, justified, and technically sound before investment.

Consultancy & Feasibility

Early-stage assessments, process reviews, sample evaluation, and ROI analysis — establishing whether automation is viable, justified, and technically sound before investment.

Consultancy & Feasibility

Early-stage assessments, process reviews, sample evaluation, and ROI analysis — establishing whether automation is viable, justified, and technically sound before investment.

System Specification & Solution Definition

Creation of URS, functional specifications, and technical requirements — defining inspection, automation, safety, data, and performance criteria for internal teams or suppliers.

System Specification & Solution Definition

Creation of URS, functional specifications, and technical requirements — defining inspection, automation, safety, data, and performance criteria for internal teams or suppliers.

System Specification & Solution Definition

Creation of URS, functional specifications, and technical requirements — defining inspection, automation, safety, data, and performance criteria for internal teams or suppliers.

Implementation Oversight, FAT & SAT

Independent support through build, factory acceptance, and site acceptance — verifying systems meet specification, perform as intended, and are ready for production use.

Implementation Oversight, FAT & SAT

Independent support through build, factory acceptance, and site acceptance — verifying systems meet specification, perform as intended, and are ready for production use.

Implementation Oversight, FAT & SAT

Independent support through build, factory acceptance, and site acceptance — verifying systems meet specification, perform as intended, and are ready for production use.

Conformance, Safety & Continuous Improvement

Post-installation review, safety and standards conformance checks, and performance optimisation — ensuring systems remain compliant, robust, and aligned with evolving production needs.

Conformance, Safety & Continuous Improvement

Post-installation review, safety and standards conformance checks, and performance optimisation — ensuring systems remain compliant, robust, and aligned with evolving production needs.

Conformance, Safety & Continuous Improvement

Post-installation review, safety and standards conformance checks, and performance optimisation — ensuring systems remain compliant, robust, and aligned with evolving production needs.

Standard engagements

Designed to reduce risk before capital is committed

Automation Readiness & Opportunity Assessment

Identify where automation, machine vision, robotics, and metrology will deliver real value — and where they will not.

Clear, independent view of automation potential across your production processes. We analyse workflows, quality risks, and operational constraints to determine which technologies are appropriate, in what order, and with what level of investment risk.

Process and constraint analysis

Unlimited expense submissions for all employees

Unlimited expense submissions for all employees

Automation, vision, robotics, and metrology suitability

Real-time budget tracking and team visibility

Real-time budget tracking and team visibility

ROI and implementation complexity ranking

Role-based access for admins, managers, and employees

Role-based access for admins, managers, and employees

Clear “do / do later / do not do” recommendations

Expense and budget reports

Expense and budget reports

Support via in-app chat and email

Support via in-app chat and email

Support via in-app chat and email

Best for

Manufacturers considering automation investment or unsure where to start.

Factory Automation Performance & Upgrade Review

Improve performance, reliability, and quality from existing automation and inspection systems.

Focuses on factories with existing automation, vision, or robotic systems that are underperforming, unreliable, or no longer aligned with production needs. We identify improvement opportunities and define whether systems should be upgraded, reconfigured, or replaced.

Review of existing automation and inspection assets

Everything in Launch, plus:

Everything in Launch, plus:

Vision and inspection performance analysis

Department-level budgeting with flexible cost center mapping

Department-level budgeting with flexible cost center mapping

Automation & robotics utilisation, downtime, and safety review

AI-powered receipt scanning and automatic extraction of structured data

AI-powered receipt scanning and automatic extraction of structured data

Data quality and traceability assessment

Approval workflows customized to your team roles and hierarchy

Approval workflows customized to your team roles and hierarchy

Performance improvement and upgrade options

Interactive dashboards with export-ready insights for operations

Interactive dashboards with export-ready insights for operations

Costed improvement pathways

Multi-filter reporting across departments, vendors, and time periods

Multi-filter reporting across departments, vendors, and time periods

Obsolescence and risk assessment

Scheduled email delivery for key reports

Scheduled email delivery for key reports

Best for

Factories seeking measurable gains without unnecessary capital spend.

Best for

Factories seeking measurable gains without unnecessary capital spend.

Best for

Factories seeking measurable gains without unnecessary capital spend.

Solution Specification & URS Development

Translate decisions into procurement-ready technical specifications. Supplier selection and commercial support.

We develop clear, supplier-ready specifications that remove ambiguity, control scope, and enable fair, comparable quotations. This ensures solutions are delivered as intended.

We manage supplier selection, technical clarification, and comparison, ensuring decisions are based on capability, risk, and value.

Functional and performance requirements

Everything in Scale, plus:

Everything in Scale, plus:

User Requirement Specification (URS)

SSO (SAML/SCIM) for secure access

SSO (SAML/SCIM) for secure access

Acceptance criteria and FAT/SAT framework

Audit logs and compliance exports

Audit logs and compliance exports

Integration and data requirements

Dedicated account manager

Dedicated account manager

Supplier evaluation criteria

SLA-backed uptime and support guarantees

SLA-backed uptime and support guarantees

Supplier shortlisting and technical clarification

SLA-backed uptime and support guarantees

SLA-backed uptime and support guarantees

Decision justification

SLA-backed uptime and support guarantees

SLA-backed uptime and support guarantees

Reduced procurement risk

SLA-backed uptime and support guarantees

SLA-backed uptime and support guarantees

Best for

Manufacturers seeking confidence and control during supplier selection.

Best for

Manufacturers seeking confidence and control during supplier selection.

Best for

Manufacturers seeking confidence and control during supplier selection.

Why AIET | Consult

We help UAE manufacturers deliver confident, connected, future-ready automation

Manufacturers invest in automation to improve quality, accelerate throughput, and strengthen competitiveness. But without clear requirements, robust testing, and ongoing performance assurance, these systems often underperform or fail to deliver expected value.

AIET combines deep domain expertise in industrial automation, machine vision, data integrity, and safety-critical engineering to ensure your automation initiatives are delivered on time, on budget, and built to last — with predictable performance, measurable results, and compliance you can demonstrate.

Strategic Planning & Requirement Definition

Clear process and inspection goal setting

Clear process and inspection goal setting

Clear process and inspection goal setting

Requirements engineering tailored to your production realities

Requirements engineering tailored to your production realities

Requirements engineering tailored to your production realities

Creation of structured specifications and acceptance criteria

Creation of structured specifications and acceptance criteria

Creation of structured specifications and acceptance criteria

Technology recommendations aligned with long-term strategy

Technology recommendations aligned with long-term strategy

Technology recommendations aligned with long-term strategy

Independent Verification & Commissioning Support

Oversight of build and configuration to specification

Oversight of build and configuration to specification

Oversight of build and configuration to specification

Structured Factory Acceptance Testing (FAT)

Structured Factory Acceptance Testing (FAT)

Structured Factory Acceptance Testing (FAT)

Site Acceptance Testing (SAT) guidance and execution

Site Acceptance Testing (SAT) guidance and execution

Site Acceptance Testing (SAT) guidance and execution

Verification of performance against defined KPIs

Verification of performance against defined KPIs

Verification of performance against defined KPIs

Conformance, Safety & Operational Integrity

Safety reviews and conformity assessments

Safety reviews and conformity assessments

Safety reviews and conformity assessments

Validation support for regulated environments

Validation support for regulated environments

Validation support for regulated environments

Data traceability and audit-ready quality reporting

Data traceability and audit-ready quality reporting

Data traceability and audit-ready quality reporting

Alignment with UAE industrial standards and best practice

Alignment with UAE industrial standards and best practice

Alignment with UAE industrial standards and best practice

Performance Assurance & Continuous Improvement

Post-go-live performance benchmarking

Post-go-live performance benchmarking

Post-go-live performance benchmarking

False reject / throughput optimisation

False reject / throughput optimisation

False reject / throughput optimisation

Root-cause analysis for quality escapes

Root-cause analysis for quality escapes

Root-cause analysis for quality escapes

Advisory support as products and processes evolve

Advisory support as products and processes evolve

Advisory support as products and processes evolve

Machine Vision & Automation

Assessment of inspection and automation opportunities across production lines

Assessment of inspection and automation opportunities across production lines

Assessment of inspection and automation opportunities across production lines

Review of existing vision systems for robustness and performance

Review of existing vision systems for robustness and performance

Review of existing vision systems for robustness and performance

Independent specification of cameras, optics, lighting, and software

Independent specification of cameras, optics, lighting, and software

Independent specification of cameras, optics, lighting, and software

Build-ready technical specifications for inspection and automation systems

Build-ready technical specifications for inspection and automation systems

Build-ready technical specifications for inspection and automation systems

Metrology & Measurement Systems

Assessment of measurement requirements against tolerance and process capability

Assessment of measurement requirements against tolerance and process capability

Assessment of measurement requirements against tolerance and process capability

Review of existing metrology systems for accuracy and repeatability

Review of existing metrology systems for accuracy and repeatability

Review of existing metrology systems for accuracy and repeatability

Specification of optical and non-contact measurement technologies

Specification of optical and non-contact measurement technologies

Specification of optical and non-contact measurement technologies

Measurement specifications, calibration strategy, and traceability definition

Measurement specifications, calibration strategy, and traceability definition

Measurement specifications, calibration strategy, and traceability definition

Robotics & Automation

Assessment of robotic suitability for handling, inspection, and measurement

Assessment of robotic suitability for handling, inspection, and measurement

Assessment of robotic suitability for handling, inspection, and measurement

Review of existing robotic cells for performance and safety

Review of existing robotic cells for performance and safety

Review of existing robotic cells for performance and safety

Specification of robots, end-effectors, and vision guidance

Specification of robots, end-effectors, and vision guidance

Specification of robots, end-effectors, and vision guidance

Alignment with safety standards, risk assessments, and regulations

Alignment with safety standards, risk assessments, and regulations

Alignment with safety standards, risk assessments, and regulations

AIET | Consult

Why advanced manufacturing consultancy?

Modern manufacturing excellence is no longer achieved through isolated automation projects. It requires a joined-up strategy across process design, machine vision, robotics, data integrity, and compliance. An advanced manufacturing consultancy provides the technical leadership needed to deliver measurable results at production scale.

AIET | Consult

Why advanced manufacturing consultancy?

Modern manufacturing excellence is no longer achieved through isolated automation projects. It requires a joined-up strategy across process design, machine vision, robotics, data integrity, and compliance. An advanced manufacturing consultancy provides the technical leadership needed to deliver measurable results at production scale.

AIET | Consult

Why advanced manufacturing consultancy?

Modern manufacturing excellence is no longer achieved through isolated automation projects. It requires a joined-up strategy across process design, machine vision, robotics, data integrity, and compliance. An advanced manufacturing consultancy provides the technical leadership needed to deliver measurable results at production scale.

From strategy to execution

Advanced manufacturing systems are complex by nature. Vision hardware, automation platforms, control software, safety architecture, and quality data must work together reliably. A specialist consultancy ensures these elements are designed as a single system, not bolted together after the fact.

From strategy to execution

Advanced manufacturing systems are complex by nature. Vision hardware, automation platforms, control software, safety architecture, and quality data must work together reliably. A specialist consultancy ensures these elements are designed as a single system, not bolted together after the fact.

From strategy to execution

Advanced manufacturing systems are complex by nature. Vision hardware, automation platforms, control software, safety architecture, and quality data must work together reliably. A specialist consultancy ensures these elements are designed as a single system, not bolted together after the fact.

Faster ROI through disciplined engineering decisions

Poorly scoped automation increases cost, risk, and downtime. An experienced consultancy defines what should be automated, when, and why — focusing investment where it delivers the greatest impact on yield, throughput, and quality performance.

Faster ROI through disciplined engineering decisions

Poorly scoped automation increases cost, risk, and downtime. An experienced consultancy defines what should be automated, when, and why — focusing investment where it delivers the greatest impact on yield, throughput, and quality performance.

Faster ROI through disciplined engineering decisions

Poorly scoped automation increases cost, risk, and downtime. An experienced consultancy defines what should be automated, when, and why — focusing investment where it delivers the greatest impact on yield, throughput, and quality performance.

Solutions designed for your process, not a template

No two production lines are the same. Effective consultancy delivers process-specific automation, tailored to your product, tolerances, volumes, and regulatory environment — rather than generic off-the-shelf systems.

Solutions designed for your process, not a template

No two production lines are the same. Effective consultancy delivers process-specific automation, tailored to your product, tolerances, volumes, and regulatory environment — rather than generic off-the-shelf systems.

Solutions designed for your process, not a template

No two production lines are the same. Effective consultancy delivers process-specific automation, tailored to your product, tolerances, volumes, and regulatory environment — rather than generic off-the-shelf systems.

Built for compliance, traceability, and long-term operation

In regulated and high-value industries, automation must be audit-ready from day one. Advanced manufacturing consultancy embeds digital traceability, validation readiness, and lifecycle support into the system design — protecting production today and scaling capability tomorrow.

Built for compliance, traceability, and long-term operation

In regulated and high-value industries, automation must be audit-ready from day one. Advanced manufacturing consultancy embeds digital traceability, validation readiness, and lifecycle support into the system design — protecting production today and scaling capability tomorrow.

Built for compliance, traceability, and long-term operation

In regulated and high-value industries, automation must be audit-ready from day one. Advanced manufacturing consultancy embeds digital traceability, validation readiness, and lifecycle support into the system design — protecting production today and scaling capability tomorrow.

Frequently asked questions

Common questions we’re asked before starting an automation or machine vision consultancy engagement

Schedule a call

Let’s talk about your application and how AIET Group can help you.

Do you prefer email? We're available at:

Schedule a call

Let’s talk about your application and how AIET Group can help you.

Do you prefer email? We're available at:

Schedule a call

Let’s talk about your application and how AIET Group can help you.

Do you prefer email? We're available at:

We provide independent technical leadership from first assessment through deployment. That typically includes process review, opportunity mapping, URS/specification writing, supplier evaluation, FAT/SAT support, and post-go-live optimisation.

Ideally before, so requirements and acceptance criteria are clear and supplier-neutral. If a supplier is already selected, we can still review scope, de-risk delivery, and verify performance against your business and compliance needs.

Yes. We produce URS, functional specifications, acceptance criteria, and test plans that procurement teams and system integrators can work from—reducing ambiguity, change requests, and project risk.

Yes. We plan and witness FAT/SAT, confirm conformance to specification, and ensure evidence is captured for auditability. We also support commissioning readiness, training requirements, and structured handover into operations.

We assess the safety concept early, align requirements to relevant standards, and ensure risk assessment and validation are addressed throughout delivery. We review guarding, interlocks, safety functions, and documentation so systems are demonstrably safe and compliant.

Both. Many clients use us purely as an independent authority; others ask us to specify and oversee delivery through trusted partners. Where AIET delivers directly, we do so with the same structured requirements, testing, and documentation discipline.

We commonly support manufacturers in industrial zones and free zones across high-precision and regulated environments—medical, aerospace, defence, pharma, and advanced industrial production—where quality, traceability, and uptime matter.

A short call, basic process context, and any existing drawings/specs or quality issues. From there we propose a focused assessment—usually a site visit plus a short written scope, risks, and next steps.

We provide independent technical leadership from first assessment through deployment. That typically includes process review, opportunity mapping, URS/specification writing, supplier evaluation, FAT/SAT support, and post-go-live optimisation.

Ideally before, so requirements and acceptance criteria are clear and supplier-neutral. If a supplier is already selected, we can still review scope, de-risk delivery, and verify performance against your business and compliance needs.

Yes. We produce URS, functional specifications, acceptance criteria, and test plans that procurement teams and system integrators can work from—reducing ambiguity, change requests, and project risk.

Yes. We plan and witness FAT/SAT, confirm conformance to specification, and ensure evidence is captured for auditability. We also support commissioning readiness, training requirements, and structured handover into operations.

We assess the safety concept early, align requirements to relevant standards, and ensure risk assessment and validation are addressed throughout delivery. We review guarding, interlocks, safety functions, and documentation so systems are demonstrably safe and compliant.

Both. Many clients use us purely as an independent authority; others ask us to specify and oversee delivery through trusted partners. Where AIET delivers directly, we do so with the same structured requirements, testing, and documentation discipline.

We commonly support manufacturers in industrial zones and free zones across high-precision and regulated environments—medical, aerospace, defence, pharma, and advanced industrial production—where quality, traceability, and uptime matter.

A short call, basic process context, and any existing drawings/specs or quality issues. From there we propose a focused assessment—usually a site visit plus a short written scope, risks, and next steps.

We provide independent technical leadership from first assessment through deployment. That typically includes process review, opportunity mapping, URS/specification writing, supplier evaluation, FAT/SAT support, and post-go-live optimisation.

Ideally before, so requirements and acceptance criteria are clear and supplier-neutral. If a supplier is already selected, we can still review scope, de-risk delivery, and verify performance against your business and compliance needs.

Yes. We produce URS, functional specifications, acceptance criteria, and test plans that procurement teams and system integrators can work from—reducing ambiguity, change requests, and project risk.

Yes. We plan and witness FAT/SAT, confirm conformance to specification, and ensure evidence is captured for auditability. We also support commissioning readiness, training requirements, and structured handover into operations.

We assess the safety concept early, align requirements to relevant standards, and ensure risk assessment and validation are addressed throughout delivery. We review guarding, interlocks, safety functions, and documentation so systems are demonstrably safe and compliant.

Both. Many clients use us purely as an independent authority; others ask us to specify and oversee delivery through trusted partners. Where AIET delivers directly, we do so with the same structured requirements, testing, and documentation discipline.

We commonly support manufacturers in industrial zones and free zones across high-precision and regulated environments—medical, aerospace, defence, pharma, and advanced industrial production—where quality, traceability, and uptime matter.

A short call, basic process context, and any existing drawings/specs or quality issues. From there we propose a focused assessment—usually a site visit plus a short written scope, risks, and next steps.