AIET |

Vision

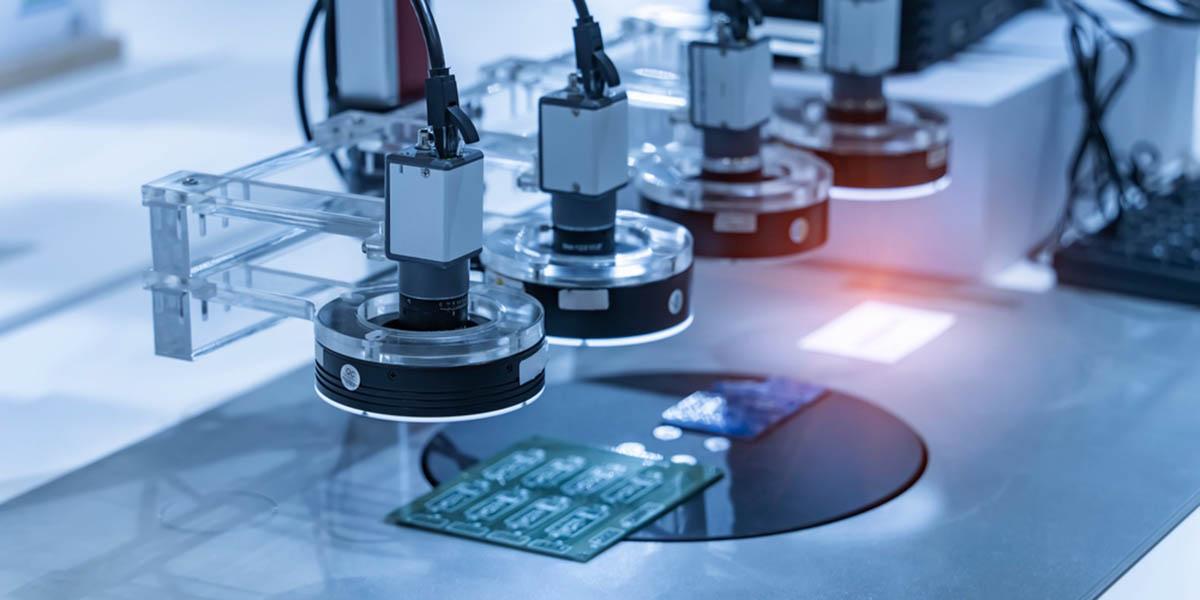

Machine Vision for High-Precision, High-Reliability Manufacturing

AI-powered inspection, defect detection, traceability, measurement, and quality control — engineered for factories building the future of UAE industry.

From feasibility to factory deployment — we design, integrate, validate, and support machine vision systems that enable real-world quality, traceability, and automation in UAE industry.

Why AIET | Vision

We deliver machine vision that works in the real world

Most vision projects fail not because of the camera — but because of poor lighting, incorrect optics, unclear requirements, or lack of integration with automation and data systems.

AIET combines 20+ years of applied vision engineering with automation, controls, and validation expertise to ensure systems don’t just detect defects — they deliver business outcomes

Inspection & Detection

Measurement & Metrology

Robotics & Automation Integration

Regulated Manufacturing & Compliance

Data, Analytics & Smart Factory Connectivity

Machine Vision Applications by Industry

We deploy advanced 2D, 3D and AI-powered inspection systems across the UAE’s most demanding sectors — from aerospace to oil & gas.

Our role isn’t to sell cameras. It’s to engineer reliable, production-ready vision systems that improve quality, reduce rework, and enable smarter manufacturing at scale.

Aerospace & Defence Manufacturing

Engineered vision systems for aerospace-grade quality control, full digital traceability, and repeatable, high-precision inspection at scale.

Advanced Manufacturing & Smart Factories

High-performance machine vision for automated quality control, robotic validation, and real-time production analytics — built to support UAE smart factory upgrades, Industry 4.0 programmes, and fully digitised production lines.

Aviation & MRO

Engineered inspection systems for aircraft maintenance, overhaul, and component lifecycle control — enabling repeatable digital inspections, reduced turnaround time, and full traceability from service bay to flight line.

Research, Universities & Innovation Labs

Flexible vision platforms for prototyping, robotics research, and AI model development — enabling UAE laboratories and accelerators to test, validate, and scale next-generation manufacturing technologies.

Government, Free Zones & National Industrial Programmes

Machine vision expertise to support industrial transformation initiatives, capability audits, and factory upgrade programmes — bridging policy, funding, and real-world deployment across the UAE manufacturing ecosystem.

Our technology partners

We work with proven global platforms in machine vision, 3D metrology, AI inspection, robotic guidance, and industrial automation — selecting the right hardware and software for each application, not just one vendor’s catalogue.

Frequently asked questions

Common questions we’re asked before starting a machine vision project