AIET |

Metrology

End-to-End Metrology for Smart, High-Precision Manufacturing

From concept to factory deployment, we help manufacturers and industrial centres unlock accurate, traceable measurement solutions that support real-world quality and production scale.

From Lab Accuracy to Line Reality

From Lab Accuracy to Line Reality

We provide depth in metrology — not just the hardware, but the systems, data flows, and capability that turn measurements into insights. Whether you need consultancy to define your measurement strategy, integration of optical/tactile systems, or full turnkey deployment tied into your production ecosystem, our team bridges the gap between manufacturing and measurement excellence.

We provide depth in metrology — not just the hardware, but the systems, data flows, and capability that turn measurements into insights. Whether you need consultancy to define your measurement strategy, integration of optical/tactile systems, or full turnkey deployment tied into your production ecosystem, our team bridges the gap between manufacturing and measurement excellence.

Consultancy & Feasibility

Independent analysis of measurement requirements, defect profiles, throughput targets, traceability demands and cost vs benefit.

Consultancy & Feasibility

Independent analysis of measurement requirements, defect profiles, throughput targets, traceability demands and cost vs benefit.

Consultancy & Feasibility

Independent analysis of measurement requirements, defect profiles, throughput targets, traceability demands and cost vs benefit.

Retrofit & Integrated Systems

Seamless addition of measurement stations into existing lines or cells, combining vision, touch probe, laser scan, and CNC metrology where needed.

Retrofit & Integrated Systems

Seamless addition of measurement stations into existing lines or cells, combining vision, touch probe, laser scan, and CNC metrology where needed.

Retrofit & Integrated Systems

Seamless addition of measurement stations into existing lines or cells, combining vision, touch probe, laser scan, and CNC metrology where needed.

Turnkey Metrology & Automation Cells

Fully-engineered measurement stations including hardware, robotics/handling, enclosure, software and trace-data integration — delivered with project oversight.

Turnkey Metrology & Automation Cells

Fully-engineered measurement stations including hardware, robotics/handling, enclosure, software and trace-data integration — delivered with project oversight.

Turnkey Metrology & Automation Cells

Fully-engineered measurement stations including hardware, robotics/handling, enclosure, software and trace-data integration — delivered with project oversight.

Regulated Validation, Traceability & Data Integration

URS/DQ/IQ/OQ documentation, calibration workflows, ISO/IEC-17025 traceability, and data-linkage into SPC/MES/Digital Twin frameworks.

Regulated Validation, Traceability & Data Integration

URS/DQ/IQ/OQ documentation, calibration workflows, ISO/IEC-17025 traceability, and data-linkage into SPC/MES/Digital Twin frameworks.

Regulated Validation, Traceability & Data Integration

URS/DQ/IQ/OQ documentation, calibration workflows, ISO/IEC-17025 traceability, and data-linkage into SPC/MES/Digital Twin frameworks.

Why AIET | metrology

We deliver measurement capability that works in the real world

Measurement systems in industrial production must survive vibration, temperature swings, operator variation, and extreme throughput demands. We combine manufacturing-grade integration and operational rigour to deliver real outcomes, not just showwork.

Core capability areas include:

2D + 3D dimensional measurement (structured light, laser triangulation, stereo)

2D + 3D dimensional measurement (structured light, laser triangulation, stereo)

2D + 3D dimensional measurement (structured light, laser triangulation, stereo)

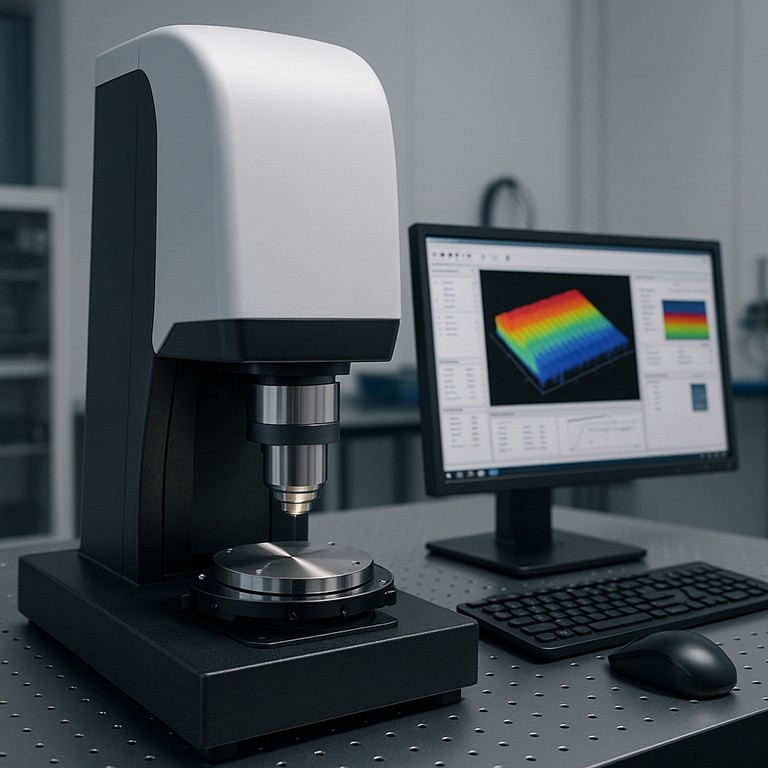

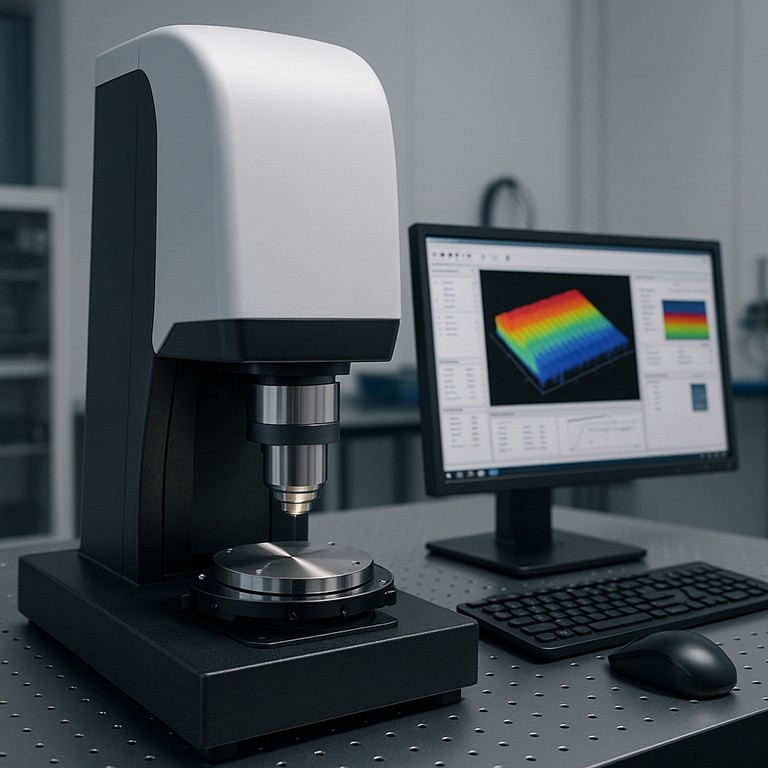

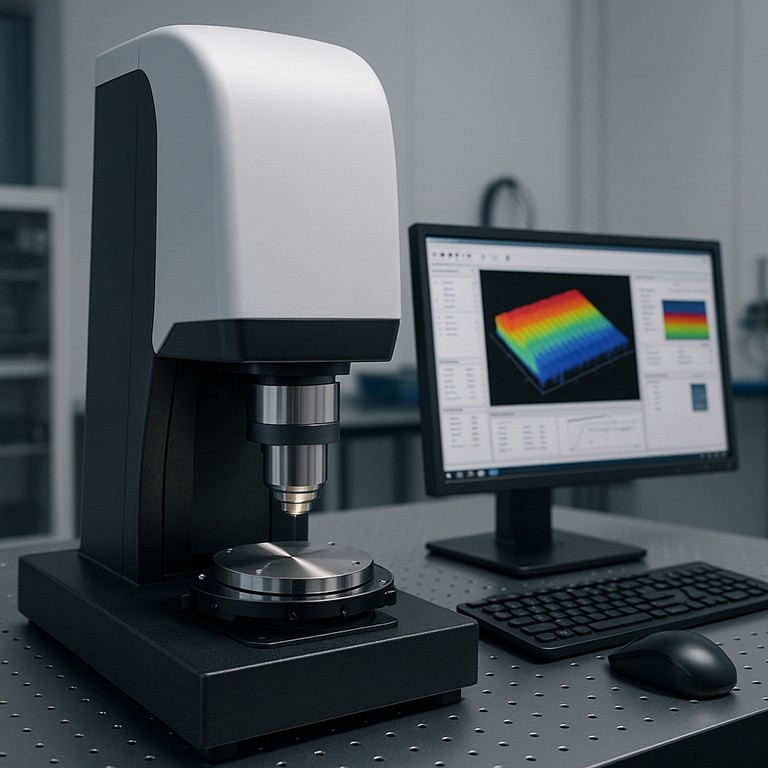

Surface and finish measurement (profilometry, roughness, form, waviness)

Surface and finish measurement (profilometry, roughness, form, waviness)

Surface and finish measurement (profilometry, roughness, form, waviness)

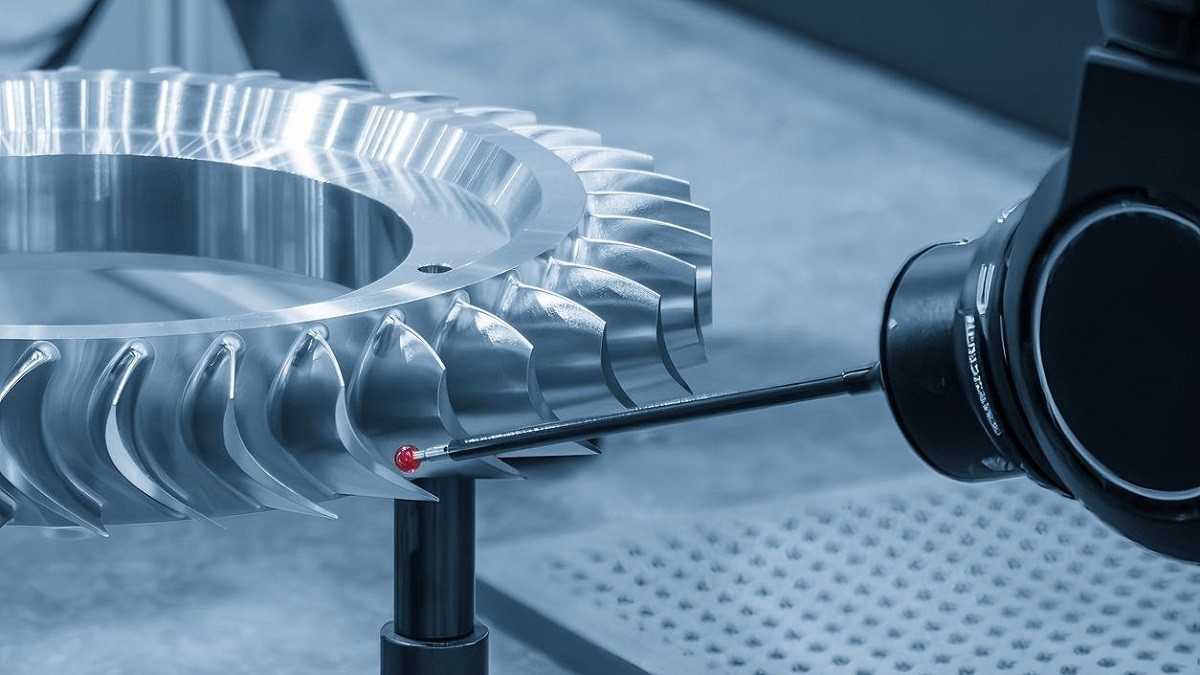

Robot-mounted and inline metrology for automation & cycle-time control

Robot-mounted and inline metrology for automation & cycle-time control

Robot-mounted and inline metrology for automation & cycle-time control

Calibration, documentation and traceability systems for aerospace, medical and defence

Calibration, documentation and traceability systems for aerospace, medical and defence

Calibration, documentation and traceability systems for aerospace, medical and defence

Data pipelines for analytics, SPC, digital twin and quality-driven manufacturing

Data pipelines for analytics, SPC, digital twin and quality-driven manufacturing

Data pipelines for analytics, SPC, digital twin and quality-driven manufacturing

Measurement & Metrology

We design, validate, and integrate measurement systems that match your part tolerances and throughput requirements.

Integrated optical and tactile metrology for micron-level precision

Integrated optical and tactile metrology for micron-level precision

Integrated optical and tactile metrology for micron-level precision

Inline gauging and feature validation tied to SPC data capture

Inline gauging and feature validation tied to SPC data capture

Inline gauging and feature validation tied to SPC data capture

CMM, laser scanning, and non-contact surface metrology integration

CMM, laser scanning, and non-contact surface metrology integration

CMM, laser scanning, and non-contact surface metrology integration

Calibration workflows traceable to ISO / IEC 17025 and NIST standards

Calibration workflows traceable to ISO / IEC 17025 and NIST standards

Calibration workflows traceable to ISO / IEC 17025 and NIST standards

Robotics & Automation Integration

True factory metrology depends on repeatable motion, handling, and measurement automation.

Vision-guided robotics for automated part positioning

Vision-guided robotics for automated part positioning

Vision-guided robotics for automated part positioning

Cobots and industrial robots for high-speed gauging and inspection

Cobots and industrial robots for high-speed gauging and inspection

Cobots and industrial robots for high-speed gauging and inspection

Adaptive measurement with auto-calibration and re-teachable tooling

Adaptive measurement with auto-calibration and re-teachable tooling

Adaptive measurement with auto-calibration and re-teachable tooling

Pass/fail and feedback loops linked directly to PLC, SCADA, or MES systems

Pass/fail and feedback loops linked directly to PLC, SCADA, or MES systems

Pass/fail and feedback loops linked directly to PLC, SCADA, or MES systems

Regulated Manufacturing & Compliance

From pharma and med-tech to aerospace and defence, compliance is integral to measurement system design.

URS, DQ, IQ, OQ, PQ documentation and validation support

URS, DQ, IQ, OQ, PQ documentation and validation support

URS, DQ, IQ, OQ, PQ documentation and validation support

Cleanroom, ATEX, sterile, and GAMP 5 environments

Cleanroom, ATEX, sterile, and GAMP 5 environments

Cleanroom, ATEX, sterile, and GAMP 5 environments

Full FAT/SAT validation with traceability and audit pathways

Full FAT/SAT validation with traceability and audit pathways

Full FAT/SAT validation with traceability and audit pathways

21 CFR Part 11, Annex 11, and e-record-ready architecture

21 CFR Part 11, Annex 11, and e-record-ready architecture

21 CFR Part 11, Annex 11, and e-record-ready architecture

Data, Analytics & Smart-Factory Connectivity

Measurement only adds value when the data drives improvement.

Direct data integration into MES, SPC, FIS, or historian systems

Direct data integration into MES, SPC, FIS, or historian systems

Direct data integration into MES, SPC, FIS, or historian systems

SPC dashboards and predictive analytics for process optimisation

SPC dashboards and predictive analytics for process optimisation

SPC dashboards and predictive analytics for process optimisation

Machine-learning feedback loops and digital-twin reinforcement

Machine-learning feedback loops and digital-twin reinforcement

Machine-learning feedback loops and digital-twin reinforcement

Full API, OPC UA, MQTT, and SQL protocol support for Industry 4.0

Full API, OPC UA, MQTT, and SQL protocol support for Industry 4.0

Full API, OPC UA, MQTT, and SQL protocol support for Industry 4.0

AIET | Metrology

Why Metrology Matters

Accurate, repeatable measurement is the foundation of modern manufacturing. Whether you’re scaling production, meeting regulatory standards, or reducing cost of quality, metrology turns parts, processes, and data into reliable, traceable outcomes. It’s not just about inspection — it’s about controlling quality, enabling automation, and building confidence into every unit you ship.

AIET | Metrology

Why Metrology Matters

Accurate, repeatable measurement is the foundation of modern manufacturing. Whether you’re scaling production, meeting regulatory standards, or reducing cost of quality, metrology turns parts, processes, and data into reliable, traceable outcomes. It’s not just about inspection — it’s about controlling quality, enabling automation, and building confidence into every unit you ship.

AIET | Metrology

Why Metrology Matters

Accurate, repeatable measurement is the foundation of modern manufacturing. Whether you’re scaling production, meeting regulatory standards, or reducing cost of quality, metrology turns parts, processes, and data into reliable, traceable outcomes. It’s not just about inspection — it’s about controlling quality, enabling automation, and building confidence into every unit you ship.

Precision

Achieve repeatable, traceable measurements — every part, every time.

Precision

Achieve repeatable, traceable measurements — every part, every time.

Precision

Achieve repeatable, traceable measurements — every part, every time.

Yield

Reduce rejects and re-work through data-driven process control.

Yield

Reduce rejects and re-work through data-driven process control.

Yield

Reduce rejects and re-work through data-driven process control.

Traceability

Maintain full digital records for audit, calibration, and compliance.

Traceability

Maintain full digital records for audit, calibration, and compliance.

Traceability

Maintain full digital records for audit, calibration, and compliance.

Insight

Transform measurement data into decisions that improve production.

Insight

Transform measurement data into decisions that improve production.

Insight

Transform measurement data into decisions that improve production.

Metrology Applications by Industry

We design and integrate 2D, 3D, and contact metrology systems for the world’s most demanding industries — from aerospace and energy to medical and precision engineering. Our focus isn’t on selling gauges; it’s on delivering production-ready measurement systems that ensure traceability, reduce variation, and drive manufacturing performance at scale.

Aerospace & Defence Manufacturing

Engineered metrology solutions for high-safety, high-precision components and assemblies.

Surface defect detection on machined or composite parts

Surface defect detection on machined or composite parts

Surface defect detection on machined or composite parts

Bore and feature measurement on turbine components

Bore and feature measurement on turbine components

Bore and feature measurement on turbine components

Serialisation and OCR/OCV for traceability in defence systems

Serialisation and OCR/OCV for traceability in defence systems

Serialisation and OCR/OCV for traceability in defence systems

Inline robot-linked gauge cells for structural sub-assemblies

Inline robot-linked gauge cells for structural sub-assemblies

Inline robot-linked gauge cells for structural sub-assemblies

Inline 3D scanning on production lines

Inline 3D scanning on production lines

Inline 3D scanning on production lines

Metrology cells interconnected via MES/SPC

Metrology cells interconnected via MES/SPC

Metrology cells interconnected via MES/SPC

Automated part sorting and re-work flagged by measurement systems

Automated part sorting and re-work flagged by measurement systems

Automated part sorting and re-work flagged by measurement systems

Predictive measurement data enabling digital twin simulation

Predictive measurement data enabling digital twin simulation

Predictive measurement data enabling digital twin simulation

Advanced Manufacturing & Smart Factories

End-to-end measurement, integration and production intelligence.

Aviation & MRO

Precision inspection and measurement systems tuned for aircraft maintenance, refurbishment and part certification.

Automated CMM stations for landing gear bearings

Automated CMM stations for landing gear bearings

Automated CMM stations for landing gear bearings

Portable measuring arms for on-wing structural inspections

Portable measuring arms for on-wing structural inspections

Portable measuring arms for on-wing structural inspections

Non-contact optical inspection for turbine blades

Non-contact optical inspection for turbine blades

Non-contact optical inspection for turbine blades

Trace-data capture for fatigue-life monitoring and compliance

Trace-data capture for fatigue-life monitoring and compliance

Trace-data capture for fatigue-life monitoring and compliance

High-resolution optical profilers for material research

High-resolution optical profilers for material research

High-resolution optical profilers for material research

Custom metrology rigs for university labs

Custom metrology rigs for university labs

Custom metrology rigs for university labs

Data integration into research analytics platforms

Data integration into research analytics platforms

Data integration into research analytics platforms

Training and capability-transfer programmes for lab-to-factory scale

Training and capability-transfer programmes for lab-to-factory scale

Training and capability-transfer programmes for lab-to-factory scale

Research, Universities & Innovation Labs

Technology enablement for academic R&D, prototyping, and industrial programmes.

Government, Free Zones & National Industrial Programmes

Advisory and programme design for measurement capability, metrology standards and industrial capability development.

Technology standards roadmap for national industrial clusters

Technology standards roadmap for national industrial clusters

Technology standards roadmap for national industrial clusters

Supplier-qualification metrology frameworks

Supplier-qualification metrology frameworks

Supplier-qualification metrology frameworks

Strategic audits of measurement infrastructure in free zones

Strategic audits of measurement infrastructure in free zones

Strategic audits of measurement infrastructure in free zones

Capability-building programmes for local workforce upskilling

Capability-building programmes for local workforce upskilling

Capability-building programmes for local workforce upskilling

Our technology partners

We work with leading global manufacturers in optical metrology, coordinate measuring machines, non-contact scanners, instrumentation and integration platforms.

Frequently asked questions

Common questions we’re asked before starting a metrologyÍ project

Schedule a call

Let’s talk about your application and how AIET Group can help you.

Do you prefer email? We're available at:

Schedule a call

Let’s talk about your application and how AIET Group can help you.

Do you prefer email? We're available at:

Schedule a call

Let’s talk about your application and how AIET Group can help you.

Do you prefer email? We're available at:

We deliver systems with micron and sub-micron resolution depending on the component, environment and throughput requirements.

Yes — we specialise in retrofit, integration, and live-line applications where downtime must be minimised.

Absolutely — our services include full documentation, calibration workflow design and traceable measurement results for regulated manufacturing.

Through detailed requirement capture, sample testing, cycle-time modelling, environment review and cost vs value analysis.

We deliver systems with micron and sub-micron resolution depending on the component, environment and throughput requirements.

Yes — we specialise in retrofit, integration, and live-line applications where downtime must be minimised.

Absolutely — our services include full documentation, calibration workflow design and traceable measurement results for regulated manufacturing.

Through detailed requirement capture, sample testing, cycle-time modelling, environment review and cost vs value analysis.

We deliver systems with micron and sub-micron resolution depending on the component, environment and throughput requirements.

Yes — we specialise in retrofit, integration, and live-line applications where downtime must be minimised.

Absolutely — our services include full documentation, calibration workflow design and traceable measurement results for regulated manufacturing.

Through detailed requirement capture, sample testing, cycle-time modelling, environment review and cost vs value analysis.